Choosing the Right Drill Bit Size for a 10-32 Tap: A Comprehensive Guide

When embarking on a threading project, precision is paramount. Selecting the correct drill bit size for your tap is crucial for creating strong, accurate threads. One of the most common tap sizes is 10-32, used in a wide range of applications from electronics to model making. Using the wrong drill bit can lead to stripped threads, broken taps, or a weak connection. This comprehensive guide will walk you through the process of determining the correct drill bit size for a 10-32 tap, ensuring your projects are successful.

Understanding Thread Tapping Basics

Before diving into specific sizes, let’s cover the basics of thread tapping. Tapping is the process of creating internal threads in a hole, allowing screws or bolts to be fastened. A tap is a tool designed with cutting edges that gradually form the threads as it’s turned into the hole. The size of the hole you drill before tapping is vital; it must be large enough to allow the tap to cut the threads, but small enough to provide sufficient material for those threads.

Major Diameter, Minor Diameter, and Pitch

Three key terms are essential to understand:

- Major Diameter: The largest diameter of the thread. For a 10-32 tap, the major diameter is approximately 0.190 inches.

- Minor Diameter: The smallest diameter of the thread, also known as the root diameter.

- Pitch: The distance between threads. For a 10-32 tap, the pitch is 1/32 inch, or 0.03125 inches.

Determining the Correct Drill Bit Size for a 10-32 Tap

The correct drill bit size is directly related to the minor diameter of the thread. The goal is to drill a hole that’s slightly larger than the minor diameter, allowing the tap to easily cut the threads without excessive force. There are several ways to determine the appropriate drill bit size.

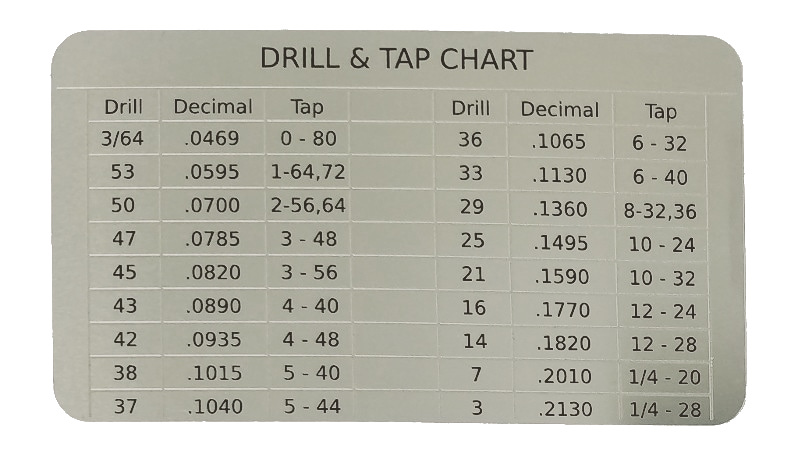

Using a Tap Drill Chart

The easiest and most reliable method is to consult a tap drill chart. These charts provide the recommended drill bit size for various tap sizes, including the 10-32 tap. For a 10-32 tap, the recommended drill bit size is typically a #21 drill bit, which has a diameter of 0.159 inches.

Tap drill charts are readily available online and in most machine shops or hardware stores. These charts often list both fractional and numbered drill bit sizes, making it easy to find the right bit.

Calculating the Drill Bit Size

If you don’t have a tap drill chart handy, you can calculate the approximate drill bit size using a simple formula:

Drill Bit Size = Major Diameter – Pitch

For a 10-32 tap:

Drill Bit Size = 0.190 – 0.03125 = 0.15875 inches

This calculation yields approximately 0.15875 inches, which is very close to the #21 drill bit size (0.159 inches) recommended by tap drill charts. This formula provides a good estimate, but always double-check with a tap drill chart for the most accurate size, especially for precision applications.

Understanding Numbered Drill Bits

Numbered drill bits are a common system used for smaller drill bit sizes. They are designated by numbers, with higher numbers indicating smaller sizes. A #21 drill bit, as mentioned, is the standard recommendation for a 10-32 tap. Familiarizing yourself with numbered drill bit sizes is crucial for anyone working with taps and threads frequently.

Factors Affecting Drill Bit Selection

While the #21 drill bit is the standard recommendation for a 10-32 tap, several factors can influence your choice:

Material Type

The type of material you are tapping significantly affects the ideal drill bit size. Softer materials like aluminum or plastic may require a slightly smaller drill bit to ensure the threads have enough material to grip. Harder materials like steel might benefit from a slightly larger drill bit to reduce the force needed to turn the tap and prevent breakage. Always consider the material’s properties when selecting your drill bit.

Thread Engagement

Thread engagement refers to the percentage of thread that is engaged by the screw or bolt. For most applications, 75% thread engagement is sufficient. However, for critical applications where maximum strength is required, you might aim for higher thread engagement. Using a slightly smaller drill bit can increase thread engagement, but be cautious not to make the hole too small, as this can make tapping difficult and increase the risk of breaking the tap.

Tap Type

Different types of taps are designed for specific purposes. For example, a spiral point tap (also known as a gun tap) is designed to push chips forward, making it ideal for through holes. A spiral flute tap pulls chips back, making it suitable for blind holes. The type of tap you use can influence the ideal drill bit size. Check the tap manufacturer’s recommendations for the best results.

Step-by-Step Guide to Tapping a 10-32 Thread

Here’s a step-by-step guide to tapping a 10-32 thread:

- Gather Your Tools: You’ll need a 10-32 tap, a #21 drill bit (or the appropriate size based on your material), a drill, a tap handle, cutting fluid, and safety glasses.

- Prepare the Workpiece: Ensure the workpiece is securely clamped or held in a vise. Mark the location where you want to drill the hole.

- Drill the Pilot Hole: Using the #21 drill bit, drill a pilot hole at the marked location. Ensure the drill is perpendicular to the workpiece to create a straight hole.

- Deburr the Hole: Use a deburring tool or countersink to remove any sharp edges or burrs around the hole. This will help the tap start smoothly.

- Apply Cutting Fluid: Apply a generous amount of cutting fluid to the tap and the hole. Cutting fluid helps to lubricate the tap, reduce friction, and dissipate heat.

- Start Tapping: Insert the tap into the hole and apply gentle pressure while turning it clockwise with the tap handle. Ensure the tap is aligned straight to avoid creating crooked threads.

- Tap in Stages: Turn the tap a few rotations, then back it out slightly to break the chips and prevent binding. Continue tapping in stages, applying cutting fluid as needed.

- Clean the Threads: Once the tap has reached the desired depth, remove it from the hole and clean the threads with compressed air or a brush.

- Test the Fit: Test the threads with a 10-32 screw or bolt to ensure a proper fit.

Troubleshooting Common Tapping Problems

Even with the correct drill bit size, you might encounter issues during the tapping process. Here are some common problems and their solutions:

- Tap Breaking: This is often caused by excessive force, insufficient lubrication, or a hole that is too small. Ensure you are using the correct drill bit size, applying plenty of cutting fluid, and avoiding excessive force.

- Stripped Threads: Stripped threads can result from using a drill bit that is too large, or from applying too much torque to the screw or bolt. Double-check your drill bit size and avoid overtightening fasteners.

- Difficult Tapping: If the tap is difficult to turn, the hole might be too small, or the material might be too hard. Consider using a slightly larger drill bit or applying more cutting fluid.

The Importance of Using the Correct Drill Bit Size

Using the correct drill bit size for a 10-32 tap is crucial for several reasons:

- Thread Strength: The correct drill bit size ensures that the threads have sufficient material to provide a strong, reliable connection.

- Tap Longevity: Using the correct size reduces the force required to turn the tap, prolonging its lifespan and preventing breakage.

- Ease of Tapping: The correct size makes the tapping process smoother and easier, reducing the risk of errors.

- Accuracy: Proper thread engagement ensures accurate and consistent results.

Conclusion

Selecting the correct drill bit size for a 10-32 tap is a fundamental aspect of thread tapping. By using a tap drill chart, calculating the size, and considering factors like material type and thread engagement, you can ensure successful and reliable results. Remember to follow the step-by-step guide and troubleshoot any common problems that may arise. With the right knowledge and tools, you can confidently tackle any threading project. Always double check your measurements and consult reliable resources to guarantee precision. Understanding the nuances of thread tapping, including the importance of the correct drill bit for a 10-32 tap, elevates your craftsmanship and ensures the longevity and reliability of your projects. Mastering the technique of selecting the right drill bit size for a 10-32 tap is an investment in the quality and durability of your work.

[See also: Understanding Thread Pitch]

[See also: Choosing the Right Tap for Your Project]

[See also: How to Use a Tap and Die Set]